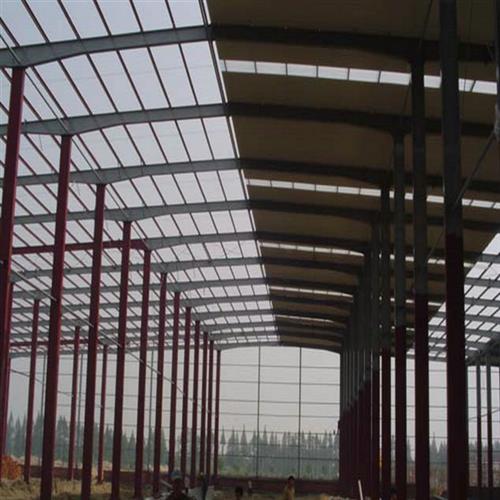

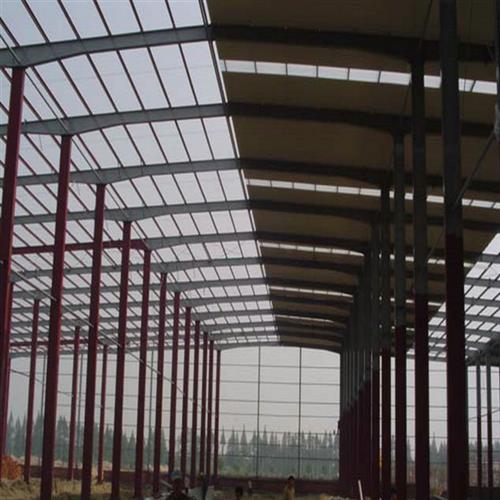

Structural steel fabricator-SBS wholesale steel buildings. SBS has steel structure warehouse project, steel structure workshop project, steel office buildings project etc. As structural steel suppliers, we take "build your future" as mission and company growth as premise. Being customer demand-oriented, SBS steel structure factory is offering all-round services to our customer with reasonable, economic, scientific and effective prefab industrial buildings solution. What is structural steel used for? Structural steel has multiple applications in the construction industry. It is used in designing and building industrial steel spaces. Structural steel has a high strength to weight ratio which makes it ideal to use in the construction of large structures such as buildings, warehouses, workshop, agricultural steel buildings, bridges, factories, etc.

With the rapid development of the national economy, steel structure building plays a more and more important role in the field of architecture. In industrial and civil buildings, steel structure occupies the market rapidly because of its outstanding characteristics. We will introduce you to some matters that should be paid attention to in the design of the steel structure factory.

The thermal conductivity of the steel is high and the thermal conductivity is 50w. When the tensile strength is above 100 °c, the tensile strength will be reduced and the plasticity will be increased. When the temperature reaches 250 °c, the tensile strength of the steel will increase slightly, but the plasticity will decrease. When the temperature reaches 500 °c, the strength of the steel decreases to a very low level, resulting in the collapse of the steel workshop building. Therefore, when the ambient temperature of the steel structure reaches 150 °C or higher, it must be designed for heat insulation and fire prevention.

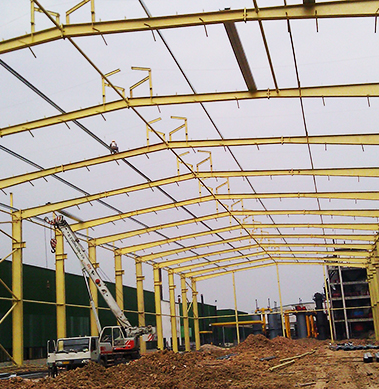

The arrangement of the roof support system should be determined according to the span and height of the steel workshop building. In general, the roof structure with or without a purlin system should be provided with vertical support. The roof with or without purlin should be provided with lateral string support on the roof rack and skylight rack. Longitudinal horizontal support should be provided for the steel structure factory with a distance of not less than 12 m. At present, there are two common methods of steel structure roof in the market: one is composed of double color profiled steel plate with insulation cotton, the other is composed of roof color steel plate, gas insulation layer, thermal insulation layer, and coil waterproof layer.

The change of temperature will lead to the deformation of steel workshop building, which will lead to the temperature stress of the structure. When the plane scale is large, in order to avoid the large temperature stress, the temperature expansion joint should be set in the vertical and horizontal directions, and the length of the section can be carried out according to the steel structure code. The temperature expansion joint is usually treated by setting double columns, and the rolling support can be set at the roof rack support for the longitudinal temperature expansion joint.

When the surface of the steel structure is exposed directly to the atmosphere, it will rust. When the corrosive medium in the air of the steel structure is in the wet environment, the corrosion of the steel structure factory will become more obvious and serious. The corrosion of steel structure not only reduces the cross-section of the member but also produces rust pits on the surface of the steel member. When the component is stressed, it will lead to stress concentration and premature failure of the structure. Therefore, full attention should be paid to the anticorrosion of steel structure factory components, and corresponding countermeasures should be taken according to the erosion medium and environmental conditions of the factory building in the aspects of general drawing arrangement, process layout, material selection and so on, so as to ensure the safety of the factory building structure. Antirust primer and topcoat are often used in anticorrosion of general steel structures, and the number and thickness of coating layers are often determined by their use environment and coating properties. Under the action of natural atmospheric medium, the coating thickness of the general indoor steel structure is 100 μ m. The total thickness of paint film is required to be 150 μ m-200 μ m for open-pit steel structure or steel structure under the action of industrial atmospheric medium. And in the acid environment of the steel structure requires the use of acid-proof paint.

How to prevent the foundation subsidence of steel structure factory should start from the foundation cap. When the steel structure building reaches above 25KG per square meter, the foundation cap needs to reach 1 meter high, 1 meter wide and 1 meter deep. When each square meter to more than 35KG, steel structure building needs to do ring beam and 1.2 meters foundation. When the steel structure factory building has been completed and the early investment has not been done well, then how should we prevent the foundation subsidence of the steel structure factory? Simply put, reinforce, ring all steel columns with I-shaped steel or channel steel to form a mesh. This method can prevent the foundation subsidence of steel structure factory building.

The foundation of steel workshop building is usually designed according to eccentric compression. For the portal rigid frame steel workshop building with low height and no crane, the connection between the column foot and the foundation is usually designed according to the hinged design. The top surface of the foundation is only subjected to the vertical pressure produced by the superstructure and the horizontal force caused by the wind load. The additional eccentric bending moment on the bottom of the foundation caused by horizontal wind load is small, and the foundation design is relatively simple. For the door rigid frame steel workshop building and the one with high height and bridge crane, especially when the crane tonnage is large, the column foot is usually designed as transverse rigid connection and longitudinal articulation. In transverse direction, because the steel structure is light in weight, the natural vibration period of the structure is long, the horizontal seismic action is relatively small, so the axial force of the two bars cannot be equal.

When the crane tonnage is large, if the eccentric distance is often the control condition of the bottom surface of the foundation, the bearing capacity of the foundation cannot be controlled when the column foot is just connected to the side column of the crane single-story steel workshop building, if the crane tonnage is large, the eccentricity is often the control condition of the bottom surface of the foundation. Large eccentricity will cause the foundation bottom size to be too large, which is very uneconomical and unacceptable in the project. With the increase of foundation depth, the soil weight on the foundation increases and the eccentricity of the foundation decreases accordingly. At this time, the foundation can be designed as a single foundation with reinforced concrete short columns. The section size of short columns is usually determined by the size of steel column foot floor, and its reinforcement is determined by calculation. However, with the increase of the buried depth of the foundation, the additional bending moment on the bottom of the foundation caused by the horizontal shear force of the column foot will also increase accordingly, and the eccentricity of the foundation may also increase. Therefore, the above two factors should be considered comprehensively in the design, and the reasonable buried depth of the foundation should be selected after trial calculation and comparison.