Material: Q235,Q345,Q420,Q460

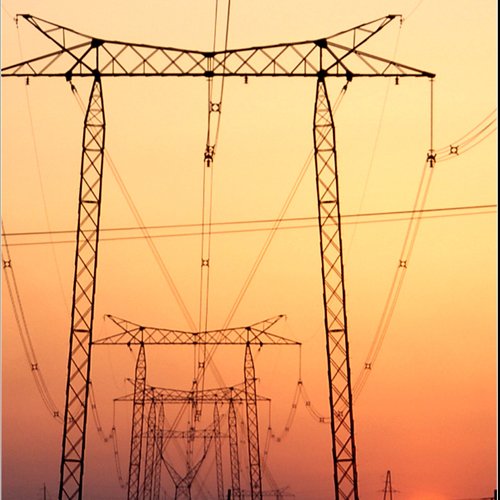

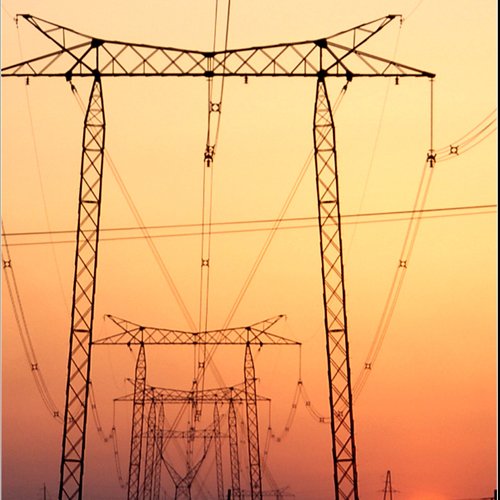

Voltage: 10KV-500KV

Galvanization: ASTM A123

Weld: CO2 Welding & Submerged Arc Auto

Surface Treatment: Hot Dip Galvanizing

Life Span: >20 years

Cetificate: ISO9001:2008

Quality. Integrity. Precision. Flexibility. On-Time Delivery. That’s what utility companies want from a steel lattice tower manufacturer. And that’s what Falcon Steel America can provide for you.

We have the ability to produce both galvanized and dulled tower steel according to your unique needs. Dulling—also known as deglaring—entails the application of consistent shading to the tower steel utilizing our state of the art proprietary formula and processes, which retain all the properties of galvanization. We can supply a wide variety of consistently dulled steel lattice towers as defined by your reflectivity range requirements.

Our in-house design team offers a broad array of services to meet our clients’ unique needs, including:

● Steel lattice transmission tower design

● Detailing

● Manufacturing

● Bundling

● Prototyping

● Shipping

Towers of self-supporting type are generally heavier than the roof top towers. They are used in the fields most commonly. Television, Microwave, Power Transmission & Lighting Masts are a few of the common applications of self-supporting towers.

We can provide various steel tower and large steel structure, such as steel angle tower, combined steel tower, flaretower, monopole tower, microwave tower, steel pole and steel framework etc, the products are widely used in electricity project, communication project, radio and television project, and other relevant projects. The foreign market, covering Europe, Southeast Asia, Middle East and Africa etc.

Owing to years of experience in the industry, we offer highly durable array of Hot Dip Galvanizing that are easily mounted in the desired area. Offered product range is thermostatically balanced and ensures durable standards. They are strong in nature and are delivered with varied voltage capacities. They are used for survey purposes and require minimum maintenance. Our firm is supported by advanced tools and techniques that assist us to meet the diverse requirement in most effective manner. Electrical towers are made of prefabricated steel structuresSurface and their treatment is Hot Dip Galvanizing.

All our products are the highest quality and satisfy requirements of competitive European and overseas market.

Features:

Excellent finishing

Reliable

High quality

Foshan Shengbang Steel Structure Co., Ltd. is one of the leading China steel pole manufacturers and suppliers, with professional factory we are always able to offer you CE certification steel poles products made in China at best price.

we have the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located.New Life Steel Structures is leading ISO 9001:2008 certified manufacturing company of prefabricated steel buildings .We are old organization having wide experience in this field with most modern Manufacturing facilities and space to handle any amount of work .SBS prefabricated steel buildings are designed to suit the demands of customers. We provide speed in delivery and erection, flexibility in expansion and withstand severest weather conditions .We also undertake complete work of pre –engineered building on turnkey basis and offer complete solution under one roof.

We are a leading manufacturer of Prefabricated Steel Structures and a Prefab Buildings Exporter in India. Our product range also comprises of Prefabricated Steel Structures, Pre Engineered Building, Prefabricated Tubular Structure and Prefabricated Building.

Advantages of pre-fabricated steels:

These are Pre-fabricated and have 100% salvage value at any time.

No welding at site is required. It is very safe for industries were welding inside plant is restricted.

Self-supporting ready-made components are used, so the need for shuttering and scaffolding is greatly reduced.

Construction time is reduced and buildings are completed sooner, allowing an earlier return of the capital invested.

On-site construction is minimized.

Quality can be controlled while the product is in production.

Less waste is generated.

Molds can be used several times.

Lower weight reduces foundation requirement.

Highly recycled and can be continued to be recycled.

Durable if protected from corrosion.