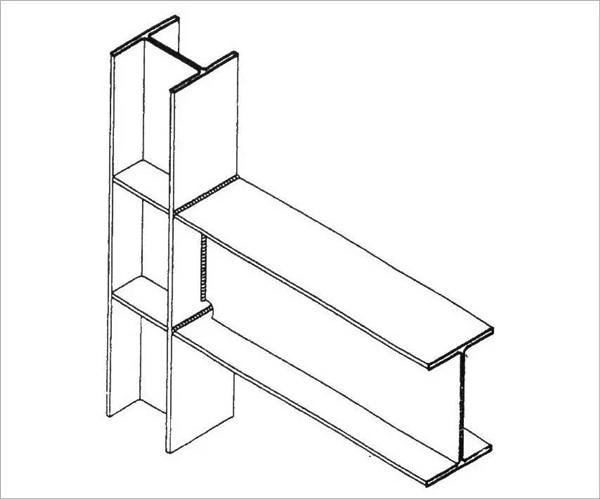

Steel structure [component connection] there are several?

Steel structure connection

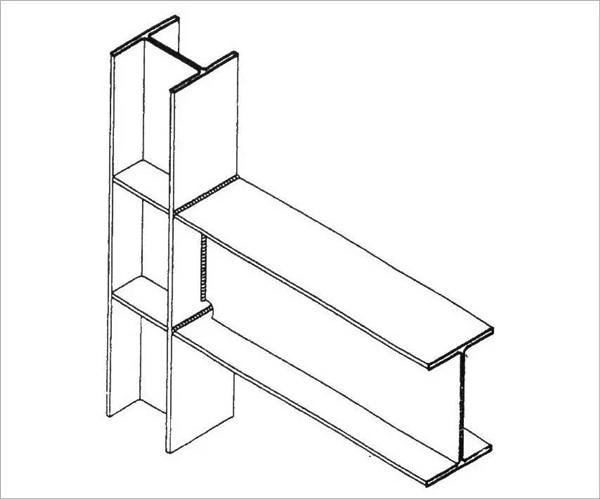

Steel structure is a prefabricated material (steel) produced by the factory into a component, and then the site of the site formed by the assembly, so the connection between the components and components of the formation of steel structure and to ensure that Structural safety is an important part of the normal work.

Design the basic principles of steel structure connection

Reasonable design of the connection, to ensure that the node has sufficient carrying capacity and the appropriate node stiffness, in order to achieve the transmission of internal force at the node.

The design should be based on the load design value generated by the structure or component internal force response to the connection node calculation.

Correctly calculating the internal force that the node receives (or passing) is the prerequisite to ensure the safety of the node. According to the force mechanism of the node connection, the appropriate connection method and the arrangement of the connection are dependent on the load characteristics of the structure or component. The size of the component, the size of the connection area, the requirements of the joint stiffness, the construction requirements of different connection methods, the possibility of construction and many other factors.

The basic way of connecting steel

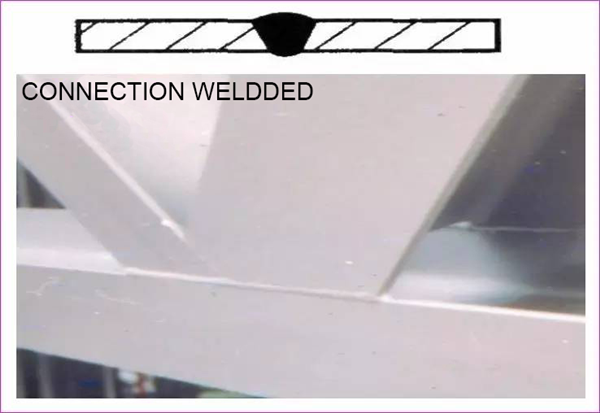

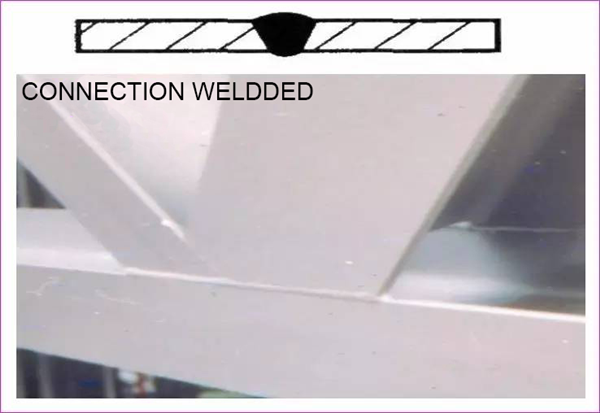

Welding connection (metallurgical type)

So that the metal melts at high temperature after the formation of the whole

Using welding materials: arc welding, gas welding, electroslag welding

Do not use welding material: resistance welding

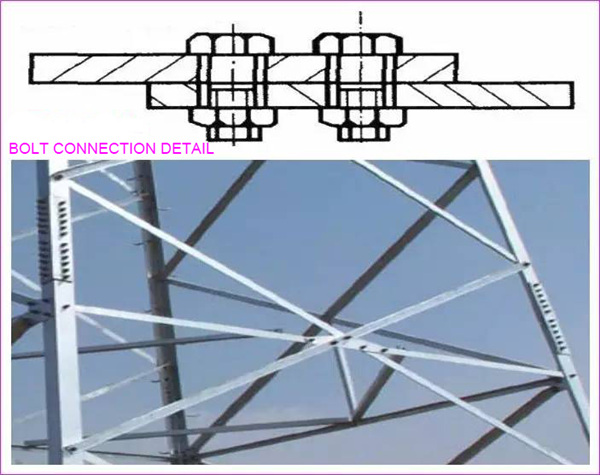

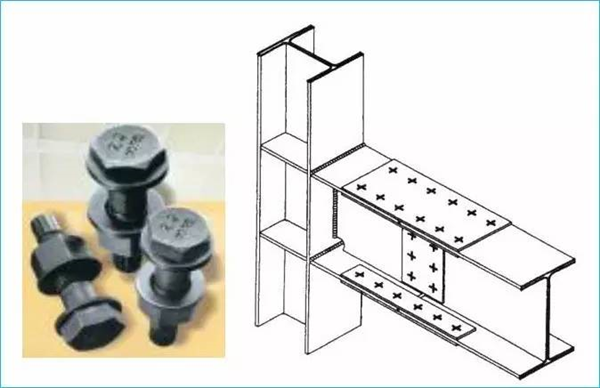

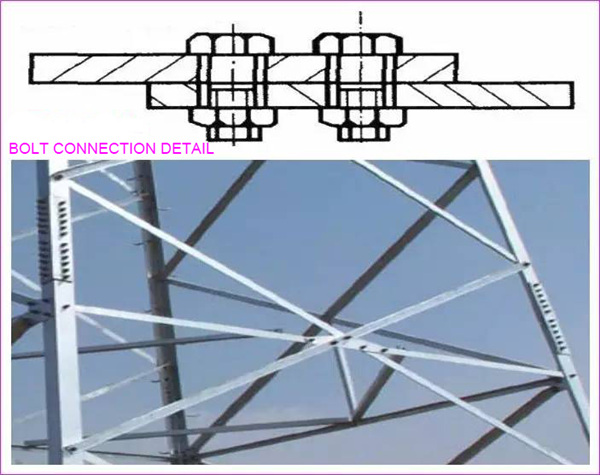

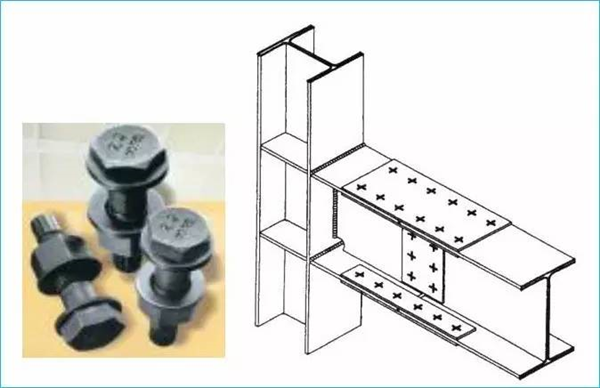

Fastener connection (mechanical)

Bolts: Common Bolts: Refined Bolts (A, B)

High strength bolts: Coarse bolts (Class C)

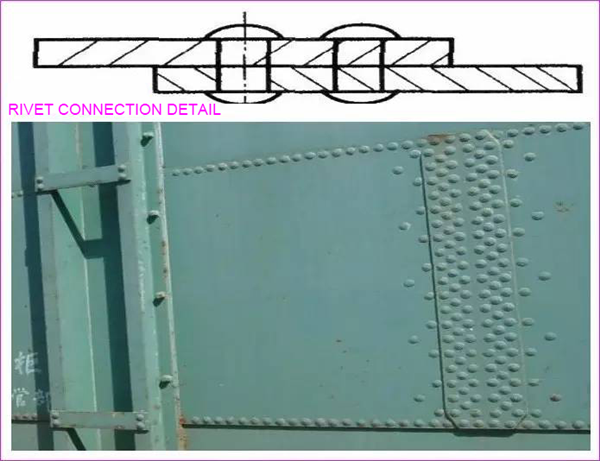

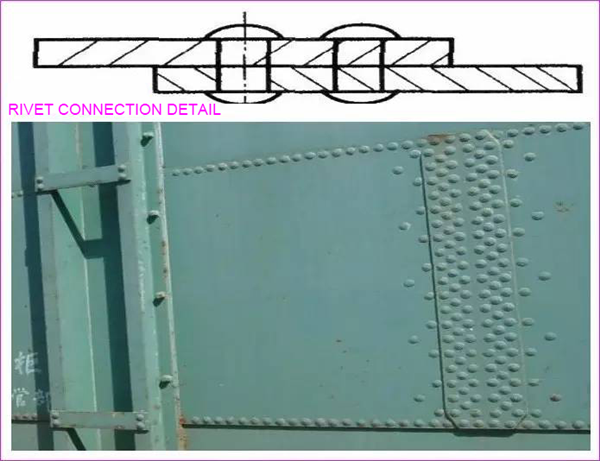

Rivets: nail connection: (nail, tapping screws, nails)

Other (chemical formula)

Strong glue: direct bonding parts

Chemical Bolt Bolt: The anchor is integrated with the anchoring foundation by means of structural glue for the connection of steel members to concrete structures

1, the characteristics of welding

advantage:

Simple construction - any shape of the components can be directly connected, without auxiliary spare parts

Provincial labor-saving material - easy processing, without drilling drilling, do not weaken the cross-section

Rapid construction - automatic operation

The connection is good, the rigidity is big and the integrity is good

Disadvantages:

Material is brittle

Resulting in residual stress, residual deformation, welding defects

On the steel structure fatigue, stability has a negative impact

More dependent on the skill level of the welder

Quality inspection requirements are higher when the inspection workload is large

Modern steel structure of the most basic connection, the most widely used

2, the characteristics of the bolt connection

advantage:

Construction is simple, easy assembly and disassembly, the requirements of the installation workers

Friction type high strength bolted connection with good dynamic performance

Resistant to fatigue, easy to prevent crack propagation

Disadvantages:

Fracture, perforated cross section weakened

Bolt hole processing accuracy requirements

3, rivets connected to the characteristics

Advantages: plastic, good toughness, good dynamic performance

Disadvantages: food, heating riveting process is extremely laborious

The current load-bearing steel structure has been rarely used

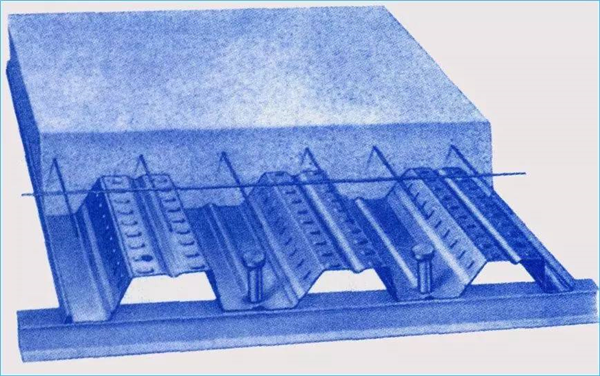

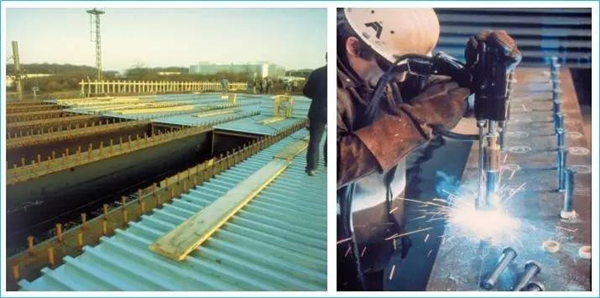

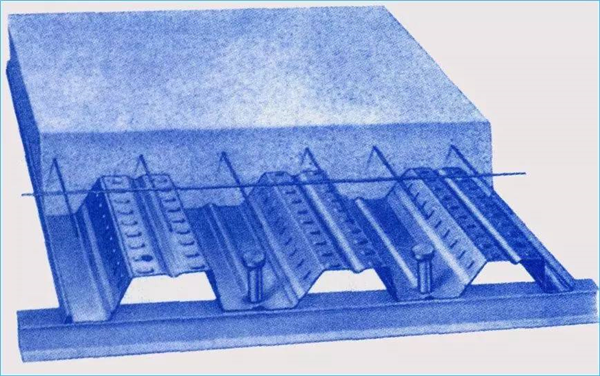

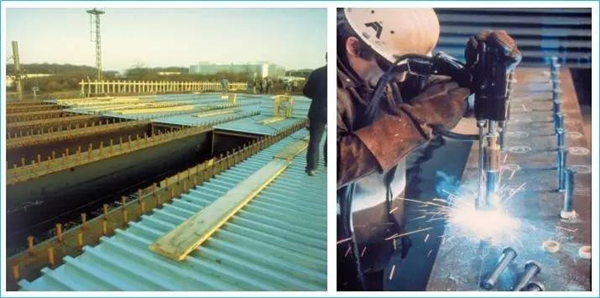

4, bolt (welding) nail connection characteristics

The pegs connect the steel plate to the concrete slab

The pegs are sheared

Weld connection form and characteristics

【Arc welding】

After the use of welding materials (welding rods or welding wire) and welding between the arc, melting welding materials to form welds, the need to use the electrode:

Manual arc welding: Q235-E43 series, Q345-E50 series Q390-E55 series of different steel connections, should be used with low-strength steel to adapt to the electrode - the quality is not easy to guarantee for field welding

Automatic (semi-automatic) submerged arc welding: Q235-H08, H08A, H08MnA welding wire, Q345, Q390- H08A, H08E, H10Mn2 - quality uniformity, plasticity, good impact toughness, for the regular component of the factory welding

【Gas shielded welding】

CO2 gas (instead of flux), welding wire, arc welding wire to form weld CO2 gas protection Welding metal and air contact

【Electroslag welding】

The use of current generated by the molten slag heat fusion filled with metal and base metal, solidified to form a connection

[Welding] The use of acetylene in the combustion of oxygen to form the flame to melt the formation of welding wire - for thin steel and small structure welding

【Resistance welding】

The use of current through the surface of the weld to be connected to the heat generated by melting the metal, through the pressure of the fusion - for the thickness of not more than 12mm steel and thin-wall welded