Causes of Leakage of Steel Structure Roof and Preventive Measures-2

Fourth, the maintenance of other leakage system analysis

Design reason

①roof rainwater system is not set according to the standard overflow measures, rainstorm intensity than the rain system emissions capacity will be more than lap joints, and even diffuse on the roof, causing accidents;

②the number of water pipes is insufficient, the rain along the gutter flow distance, a long time, resulting in backwater; Wall outside the plate is not added L-shaped side pieces, resulting in hidden inside the gulf hidden trouble;

③ Color steel flooding parts design unreasonable, fail to achieve waterproof effect.

④The specification of the deformation control value of the component, the purlin deflection L / 180, the roof beam deflection L / 180 (where L is the span of the bending member), the roof purlin section design is too small, the spacing is too large, under the wind load purlin and Pressure plate deformation will be too large;

⑤not fully consider the structural deformation, temperature deformation, dry shrinkage deformation, vibration and other effects, fortification does not meet the needs of grass-roots deformation.

⑥door frame light housing roof slope should take 1/8 ~ 1/20, in the rain more areas should take one of the larger value, the southern area of the roof slope should not be less than 5%. In the actual design project, many of the project roof slope is too small, the roof rain can not be discharged to the gutter in time.

Improper selection of materials

①rain pipe with plastic pipe, the intensity is poor, steel plant from the installation to the production run, easy to damage.

②steel for the gutter is relatively thin, easy to weld problems.

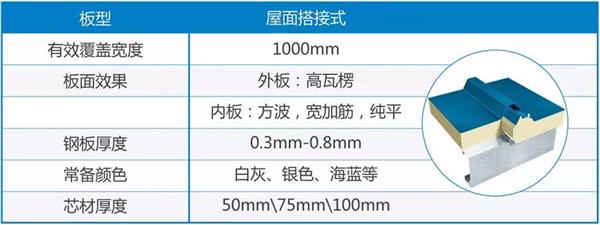

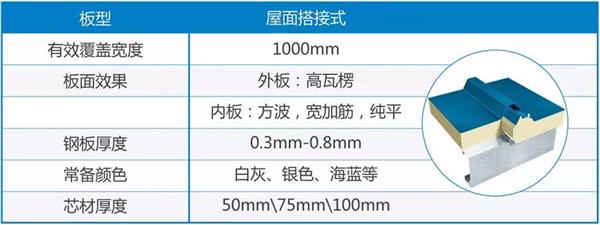

③not according to the slope of the roof to choose the appropriate lighting board plate and roof color plate type, smaller peaks, lateral overlap too little is not conducive to drainage.

④enclosure part of the color plate is too thin, after a period of use, the outer plate corrosion or deformation by the temperature, the gap between the plates increased.

⑤pressure plate substrate galvanized layer quality is not good, the coating is too thin, resulting in the use of pressure plate short, easy to corrosion damage;

⑥self-tapping screw pad poor quality easy to crack, easy to aging glass sealant.

⑦buckle plate significantly deformed, adjacent two plates of the board height, spacing are different; Buckle pull nails should be waterproof pull nails.

Constructive measures

①plug on the seam caused by the leakage is a role, should not be overlooked, such as to ensure that the color plate and roof cover plug installed in place, lighting board and roof cover between the lower part of the application of silicone sealant, Hole at the end of the steel plate set the steel plug;

②lap when the gap is susceptible to temperature changes, should be sufficient to stay enough lap length;

③water should be sparse should not block, the general installation of the inside of the steel plate to seal the glue, the more the better;

④must be sufficient attention to steel roofing system thermal expansion and contraction of the adverse effects, to take reasonable structural measures.

While using it

①roof purlin on the random increase in load, resulting in roof deformation.

②rain cast more sewage, there is water blocking.

③waterproof glue, sealant aging, the use of the process of the lack of necessary maintenance.

Concluding remarks

There are many factors that cause the leakage of the steel structure maintenance system. In order to solve the problem fundamentally, it is necessary to design seriously, to make a reasonable design, to do a good job (the waterproof layer of the head), two seam (deformation seam, ), Three (water mouth, entrance, cornice) and four (daughter wall root, equipment root, pipe root, chimney root) and other parts of the water parts of the detailed treatment; from the construction, the development of maintenance system waterproof construction of special programs, Coordinate with each other. Well-designed, installed in place, reasonable structure, proper use, service follow-up, so as to ensure that the steel structure maintenance system drip leak. In short, regardless of the use of any form of installation, as long as in accordance with certain construction techniques and the relevant provisions, can reduce or avoid leakage problems.