1.Product Detail information

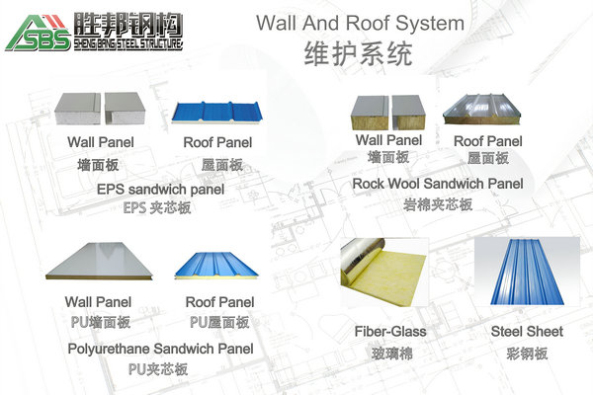

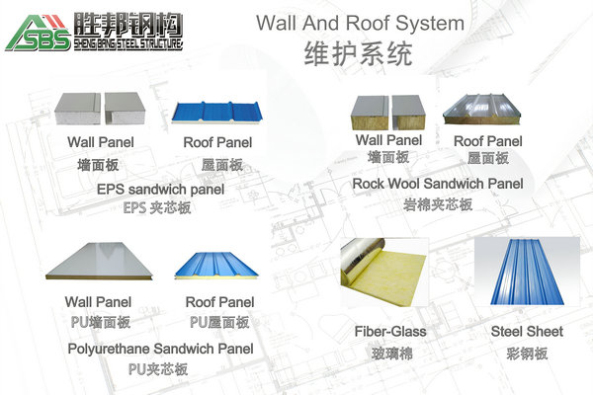

1)Steel Structure Panel material

The steel structure panel material included EPS sandwich panel,Rock wool sandwich panel,PU sandwich panel,fiber-glass ,steel sheet.

1)FIBER GLASS

Glass wool adopts the most advanced centrifugation technique to fiber glass fibrosis, Such products has large amount and very thin glass fiber inside. Its total surface area is very large also, so as to strengthen the resistance of the air, making the air unable to flow and eliminating the air convection heat transfer; Similarly, huge friction decays vibration of the sound propagation carriers - air quickly, which ensures glass wool's good thermal insulation and sound absorption effect. It is also good material for sound absorption and noise reduction in steel structure building.

2)Rock Wool Sandwich Panel

Rock wool sandwich panel is not better than polystyrene and polyurethane sandwich panel with regard to sole weight, heat conduction, compressive strength, water absorption rate and other physical and mechanical properties. However, it can be used under the service temperature of 600℃. Besides, this type panel possesses the outstanding feature of being level A incombustibility, thus rock wool sandwich panel serviceable range is expanded to light weight construction materials for high requirement on fire-protection rating.

2.Product Details

|

Usage

|

Steel Structure workshop,warehouse,office or so on.

|

|

Size

|

length*width*high, and the ridge height, slope

|

|

Standard

|

China Standard,England Standard,America Standard or Australia Standard(please supply the detail date)

|

|

Crane

|

Do you need the crane?If you need please tell me the loding.

|

|

Country

|

Which country that the building will be?

|

|

Design load

|

Wind speed, Snow load, Earthquake

|

|

Wall and Roof

|

Steel sheet or sandwich panel

|

|

Insulation

|

Fiber glass, EPS,Rock wool,PU,please tell me the thickness

|

|

Surface

|

Painted (alkyd paint or Epoxy paint) ,Hot dip galvanize

|

|

Window

|

Quantity, material, dimension (W*H) and position

|

|

Door

|

Quantity, material, dimension (W*H) and position

|

|

Accessories

|

Down pipe, Out gutter, Ventilator, skylight etc.

|

3.Advantages

1) Features: fast and flexible to assemble, safe, thermal and noise insulation, water proof and fire prevention;

2) Cost-effective: Fast and easy installation greatly shorten the construction time which reduce the costs;

3) Durability: The whole structure is easy in maintenance, which can be used for more than 50 years.

4) Perfect design: Perfect design completely avoids leaks and water seepage. Meanwhile, it's also in line with the national level of fire prevention.

5) Carrying capacity: can resists the impact of strong wind and seismic performance and bears heavy snow loads.

Due to the above advantages, combination of light china steel building structures in construction engineering, railway, petrochemical industry, water conservancy construction highway construction and military engineering and earthquake relief in the fields of temporary is widely used in construction.

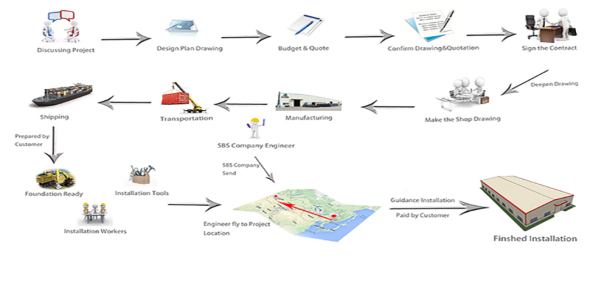

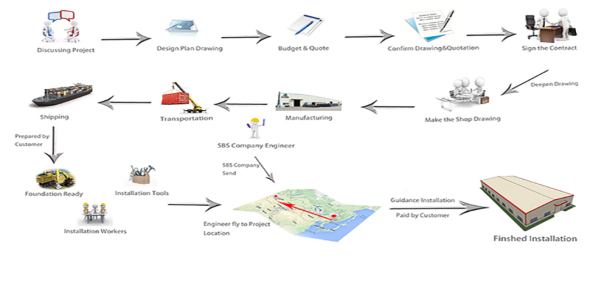

4.Service flow path

Discussing Project——Design Plan Drawing——Budget & Quote——Confirm Drawing&Quotation——Sign the Contract——Make the shop Drawing——Manufacturing——Transportation——Shipping——Foundation Ready——Guidance Installation——Finshed Installation

5.Market:

6.Company Profile:

Foshan Shengbang Steel Structure Co., Ltd.Possesses professional large-scale steel structure production equipments and the automatic spraying production

line, so we can satisfy the different customers demand.We takes "build your future" as mission and takes company growth as premise.The company has trained many

high quality marketing personnel, professional technician and construction workers.We take the customers' demand as the guidances, then provide reasonable,

scientific and effective solution for customers.We regard practical growth, innovationand group solidarity as our company spirit, so that we can offer all round service to customers.