Prefabricate steel structure Workshop

GAS sheielaed are welding

welding wire flongation

the welding wire elongation relates to the wire diameter,the welding electric current and the welding voltage.

during the welding process,the distance between contact tube to the base material is generally as 10-15 times as the welding wire diameter.

wire electric current

stick up the principe that base materials are in the well welding penetretion,welding current should be accurately selected in accordance with thickness of base materials,joint type and the wire diameter.

the range of welding electric current in common use variety of variety of welding diameters shown in table A2

|

diameter

|

0.5

|

0.6

|

0.8

|

1.0

|

1.2

|

1.6

|

|

Electric

|

30-70

|

49-90

|

50-120

|

70-180

|

90-350

|

150-500

|

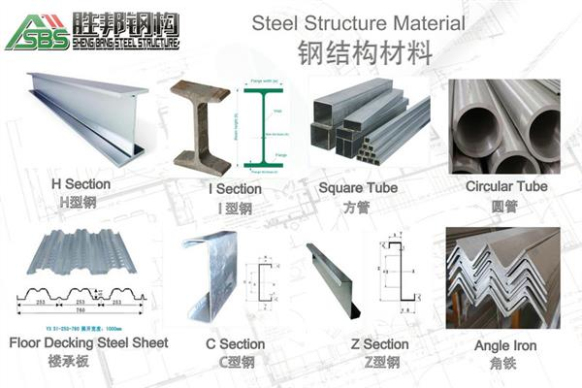

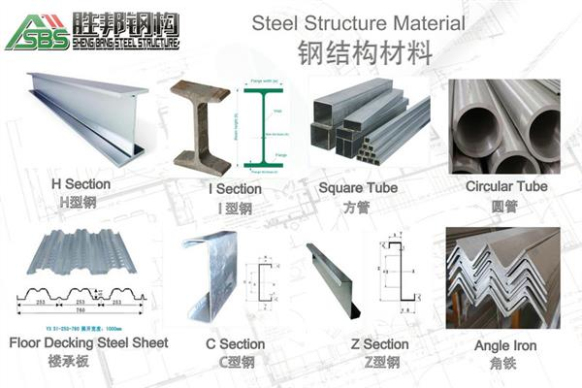

1、Product Detail information

1)Steel Structure Panel material

The steel structure panel material included PU sandwich panel,EPS sandwich panel,fiber-glass ,Rock wool sandwich panel,steel sheet.

Steel structure panel material are including wall panel and roof panel

Sandwich core materials: EPS, PU, rock wool, glass wool

Thickness of sandwich panels: 50mm, 75mm, 100mm, 150mm

Single color plate material thickness: 0.376mm, 0.426mm, 0.476mm

2、Technical Parameters

|

Lifting capacity(t)

|

t

|

5

|

10

|

|

Span(m)

|

s

|

10.5-31.5

|

10.5-31.5

|

|

Lifting height(m)

|

|

16

|

16

|

|

Trolley moving speed(m/min)

|

|

37.2

|

43.8

|

|

Trolley lifting speed(m/min)

|

A5

|

12.5

|

8.5

|

|

Crane running speed(m/min)

|

A6

|

15.5

|

13.3

|

|

A5

|

89.8 92.3 89.8 91.9 84.7

|

|

A6

|

116.2 117.4 115.6 116.8 112.5

|

|

Power source

|

|

A.C380V 50HZ 3-Phase

|

3、Advantages

1) Features: fast and flexible to assemble, safe, thermal and noise insulation, water proof and fire prevention;

2) Cost-effective: Fast and easy installation greatly shorten the construction time which reduce the costs;

3) Durability: The whole structure is easy in maintenance, which can be used for more than 50 years.

4) Perfect design: Perfect design completely avoids leaks and water seepage. Meanwhile, it's also in line with the national level of fire prevention.

5) Carrying capacity: can resists the impact of strong wind and seismic performance and bears heavy snow loads.

combination of light china steel building structures in construction engineering, railway, petrochemical industry, water conservancy construction highway construction and military engineering and earthquake relief in the fields of temporary is widely used in construction.

4.Transportation

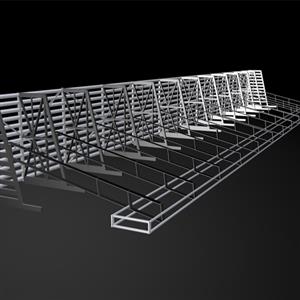

Steel structure is mainly composed of steel column, steel beam, steel frame and the rigid support and so on, so steel structure component volume is larger, The mainly transportation for export is as follow:

1). Seaworthy

In general, after customer order, our engineering technology department design the steel structures will be according to the 40 'HQ and 40' open top container inside size to design the shipment, in most cases, we use 40 'HQ and 40' open top shipping container shipment to pack steel structures.

2).Package for the steel frame

If you want to use the 40 HQ container to transportation the whole steel structure product. You can do the steel frame to package ,use the cable wire to fix. But you must paid for the steel frame and baling charges.

5.Company Profile:

Foshan Shengbang Steel Structure Co., Ltd.Possesses professional large-scale steel structure production equipments and the automatic spraying production

line, so we can satisfy the different customers demand.We takes "build your future" as mission and takes company growth as premise.The company has trained many

high quality marketing personnel, professional technician and construction workers.We take the customers' demand as the guidances, then provide reasonable,

scientific and effective solution for customers.We regard practical growth, innovationand group solidarity as our company spirit, so that we can offer all round service to customers.