Steel structure large steel supermarket

1.Steel structure large steel supermarket Benefits

Using a combination of metal construction and pre-fabricated components provides three main advantages:

1)Cost:

Because erection labor is drastically reduced, you can save as much as 30% or more over more traditional construction methods.

2)Speed:

Because many of the components are pre-fabricated at our plant, construction time is greatly reduced.

3)Durability:

Steel building components are guaranteed to last 20 to 30 years without repainting or other maintenance.

2. Product Detail information

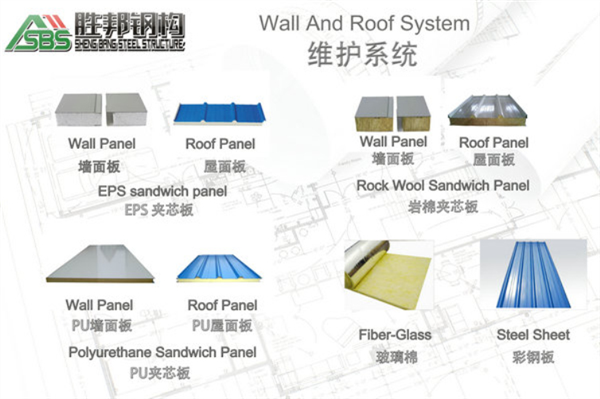

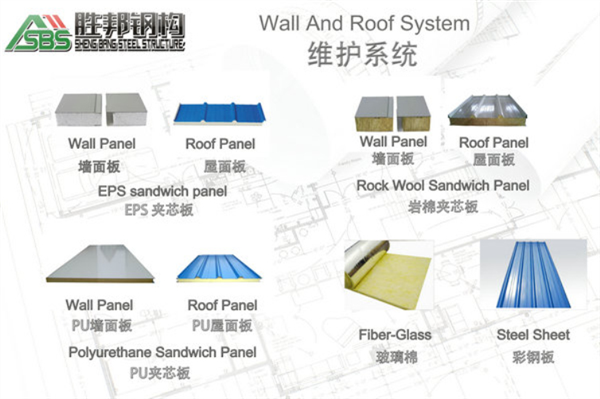

1) Steel Structure Panel material

FIBER GLASS

Glass wool adopts the most advanced centrifugation technique to fiber glass fibrosis, Such products has large amount and very thin glass fiber inside. Its total surface area is very large also, so as to strengthen the resistance of the air, making the air unable to flow and eliminating the air convection heat transfer; Similarly, huge friction decays vibration of the sound propagation carriers - air quickly, which ensures glass wool's good thermal insulation and sound absorption effect. It is also good material for sound absorption and noise reduction in steel structure building.

2)Rock Wool Sandwich Panel

Rock wool sandwich panel is not better than polystyrene and polyurethane sandwich panel with regard to sole weight, heat conduction, compressive strength, water absorption rate and other physical and mechanical properties. However, it can be used under the service temperature of 600℃. Besides, this type panel possesses the outstanding feature of being level A incombustibility, thus rock wool sandwich panel serviceable range is expanded to light weightconstruction materials for high requirement on fire-protection rating.

3. Provide data

|

Item Name

|

Steel structure building

|

|

Size

|

Length, Width, Roof height and Eave Height

|

|

Roof and Wall

|

PU, EPS, Rock Wool sandwich panel

|

|

Door and Window

|

PVC or Aluminum Alloy

|

|

Column and Beam

|

Hot rolled H section , I section or Galvanized

|

|

Purlin

|

C-Section and Z-section

|

|

Surface

|

2 primer and 1 finished paint

|

|

Local Climate

|

1. wind speed 2. Rain load 3. Snow load 4. Earthquake grade if any, etc.

|

|

Crane parameter

|

If need crane beam, parameter is in need.

|

|

Drawing

|

1. Quote as clients' drawing

2. Design as per clients' requests.

|

|

Package

|

In container or as per requests.

|

|

Load in

|

20 ft', 40 ft' GP, /HQ/OT container

|

4. Transportation

Steel structure is mainly composed of steel column, steel beam, steel frame and the rigid support and so on, so steel structure component volume is larger, The mainly transportation for export is as follow:

1) Seaworthy

In general, after customer order, our engineering technology department design the steel structures will be according to the 40 'HQ and 40' open top container inside size to design the shipment, in most cases, we use 40 'HQ and 40' open top shipping container shipment to pack steel structures.

2) Package for the steel frame

If you want to use the 40 HQ container to transportation the whole steel structure product. You can do the steel frame to package ,use the cable wire to fix. But you must paid for the steel frame and baling charges.

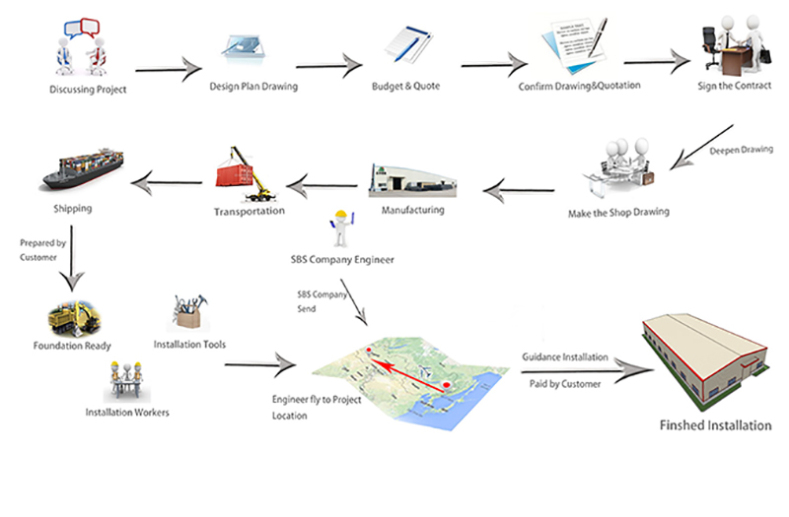

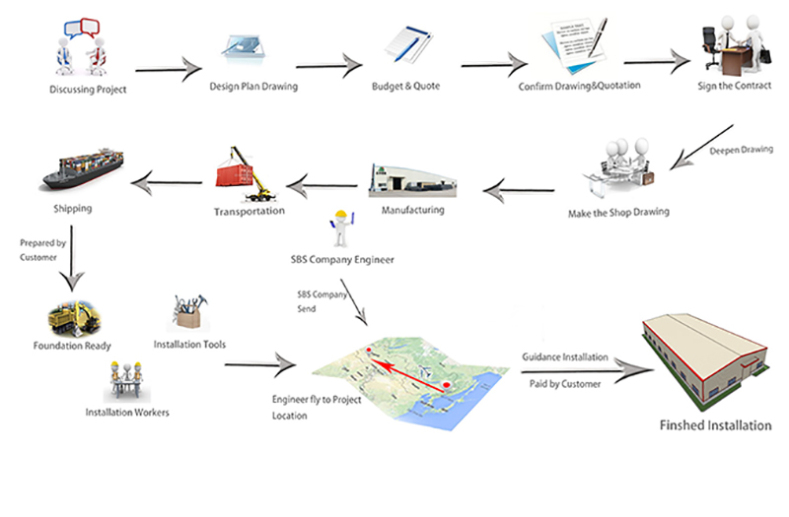

5. Service flow path:

Discussing Project——Design Plan Drawing——Budget & Quote——Confirm Drawing&Quotation——Sign the Contract——Make the shop Drawing——Manufacturing——Transportation——Shipping——Foundation Ready——Guidance Installation——Finshed Installation

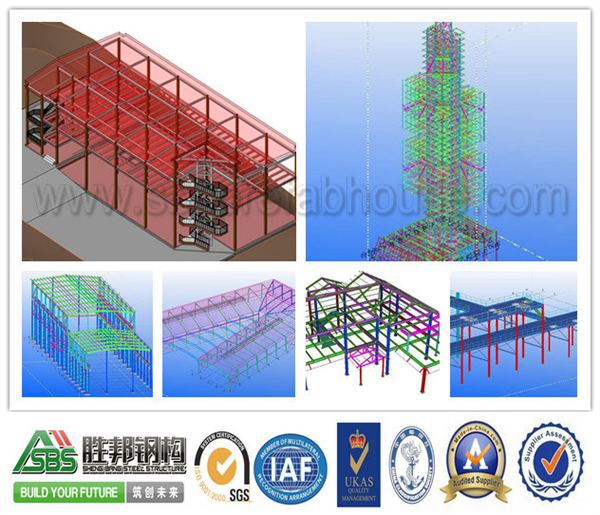

Company Profile:

Foshan Shengbang Steel Structure Co., Ltd.Possesses professional large-scale steel structure production equipments and the automatic spraying production

line, so we can satisfy the different customers demand.We takes "build your future" as mission and takes company growth as premise.The company has trained many

high quality marketing personnel, professional technician and construction workers.We take the customers' demand as the guidances, then provide reasonable,

scientific and effective solution for customers.We regard practical growth, innovationand group solidarity as our company spirit, so that we can offer all round service to customers.